The mining industry is rapidly integrating cutting-edge technologies to optimize processes and enhance safety. Among these innovations, 3D laser scanners are emerging the field of mine design. These advanced devices provide highly accurate three-dimensional models of underground spaces, allowing engineers to create more efficient mine plans and reduce potential risks.

With 3D laser scanners, geologists can survey vast amounts of terrain data with unparalleled efficiency. This live information allows for more intelligent decision-making throughout the mine design process. Engineers can visualize different mining scenarios, locating potential hazards and optimizing resource extraction strategies.

- Furthermore, 3D laser scanners enable the creation of digital twins of mines. These virtual replicas provide a holistic representation of the mining operation, allowing for instantaneous monitoring, evaluation of performance, and pinpointing of potential issues before they worsen.

- Moreover, the use of 3D laser scanners in mine design advances to greater safety by allowing for the pinpointing of potential hazards, such as unstable ground conditions or gas leaks. This foresightful approach helps to mitigate risks and protect the health of mining personnel.

Through conclusion, 3D laser scanners are redefining mine design by providing highly accurate data, enabling effective planning, and boosting safety. As this technology continues to advance, it is poised to substantially transform the mining industry.

Unveiling Underground Potential: Mining Laser Scanner Applications

The mining industry is rapidly evolving, seeking innovative solutions to optimize efficiency and boost safety. Laser scanning technology has emerged as a transformative tool, offering a comprehensive view of underground environments. By employing highly precise laser beams, these scanners create detailed 3D models of mine sites, encompassing everything from geological formations to infrastructure. This abundance of data provides invaluable insights for a variety of applications, including resource extraction planning, structural monitoring, and hazard identification.

Mining laser scanners permit real-time data capture, allowing engineers and geologists to visualize complex mine layouts with unprecedented accuracy. This power to accurately represent underground spaces in 3D revolutionizes the way mines are planned, operated, and sustained. Furthermore, laser scanning plays a crucial role in ensuring worker safety by pinpointing potential hazards such as unstable rock faces or structural weaknesses.

- By complementing traditional surveying methods, laser scanners provide enhanced precision and detail.

- Leveraging this technology enables efficient deployment of resources.

Laser Accuracy: Leveraging Laser Scanning in Mine Planning

Mining operations demand strict accuracy to ensure both maximum resource extraction and the safety of personnel. Traditional surveying methods, while reliable, can be time-consuming and prone to human error. Leveraging laser scanning technology presents a transformative solution for mine planning projects by providing detailed 3D models with exceptional precision. Laser scanners emit beams of light that return from surfaces, creating a cloud of data points. This data is then processed to generate highly accurate representations of the mine site, encompassing topography, geological features, and existing infrastructure.

- Additionally, laser scanning enables real-time monitoring of developments in the mine environment, facilitating dynamic adjustments to operations

- Therefore, risks are minimized and project timelines are streamlined.

Ultimately, integrating laser scanning into mine planning workflows empowers mining companies to make data-driven decisions, leading to increased productivity. It's a powerful tool that drives the entire mining process from exploration to extraction.

Laser Scanning Technology: A Game-Changer for Modern Mining

The resource acquisition industry is undergoing a radical transformation, driven by the implementation of cutting-edge technologies. Among these innovations, laser scanning has emerged as a game-changer. This non-destructive method provides highly accurate 3D representations of open pits, offering unprecedented insights into geological formations, ore bodies, and structural characteristics.

- Leveraging laser scanning allows mining companies to optimize extraction processes, enhance safety protocols, and reduce operational costs.

- By providing detailed mapping of the mine environment, laser scanning enables better planning of blasting operations, reducing waste and optimizing efficiency.

- Moreover, laser scanning facilitates real-time monitoring of deformations, ensuring early detection of potential hazards and reducing risks to personnel and equipment.

The adoption of laser scanning technology is rapidly becoming mandatory for modern mining, enabling a shift towards a smarter and sustainable industry.

Leveraging Data into Actionable Insights with 3D Laser Scanners

In today's dynamic landscape, enterprises are constantly seeking innovative ways to derive valuable insights from the vast amounts of data generated daily. Cutting-edge technologies, such as 3D laser scanners, offer a transformative approach for capturing and analyzing complex spatial information. By converting raw point clouds into actionable insights, these scanners empower professionals across diverse industries to make informed decisions and optimize their processes.

Leveraging the capability of 3D laser scanning, organizations can precisely document physical assets, create detailed models, and discover potential issues. This treasure of spatial data enables a wide 3D laser Scanners range of applications, including manufacturing monitoring, inventory management, and environmental analysis.

- Moreover, 3D laser scanners offer numerous benefits over traditional surveying methods. Their resolution is significantly superior, allowing for the capture of even the most intricate details. Additionally, they are non-invasive and safe, minimizing interference on operations.

- Furthermore, the rapid data acquisition capabilities of 3D laser scanners allow for quick assessment. This time-saving aspect is essential in industries where choices need to be made promptly.

Consequently, 3D laser scanning technology is revolutionizing the way data is collected, analyzed, and used to drive results. By embracing this innovative approach, organizations can unlock a new level of performance and gain a competitive edge in today's demanding market.

Optimizing Extraction Efficiency with Advanced Laser Scanning Techniques

The sector of laser scanning is rapidly advancing, leading to innovative techniques for achieving improved extraction efficiency. These cutting-edge methods leverage the precise and non-invasive nature of laser light to acquire high-resolution data, enabling detailed analysis and retrieval of valuable information. By utilizing advanced algorithms and sophisticated platforms, researchers and practitioners can process laser scan data to identify hidden patterns, create 3D models, and optimize various extraction processes.

Among the notable advancements in laser scanning technology are hyperspectral imaging, which allows for the capture of data across multiple wavelengths, providing rich information about the object. Moreover, techniques such as LiDAR (Light Detection and Ranging) offer exceptional precision in measuring distances and creating detailed geographical representations. These powerful tools have revolutionized fields like archaeology, crime scene investigation, and environmental monitoring, enabling improved extraction of information from diverse sources.

Mara Wilson Then & Now!

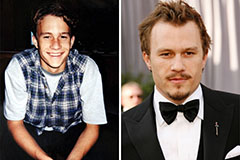

Mara Wilson Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Marla Sokoloff Then & Now!

Marla Sokoloff Then & Now! Mary Beth McDonough Then & Now!

Mary Beth McDonough Then & Now! Teri Hatcher Then & Now!

Teri Hatcher Then & Now!